Hardware Design Files

This folder is reserved for KiCad hardware design files for the DCC Locomotive Decoder.

Planned Contents

- Schematic: Complete circuit schematic (

.kicad_sch) - PCB Layout: Printed circuit board design (

.kicad_pcb) - Bill of Materials: Component list (BOM.csv)

- Gerber Files: Manufacturing files

- 3D Models: Component models

- Assembly Drawings: Assembly instructions

Current Status

🚧 Under Development

Hardware design files will be added in future releases.

Design Goals

- Compact form factor suitable for HO/N scale locomotives

- Single or dual-sided PCB (TBD)

- Through-hole or SMD components (TBD)

- Easy assembly and testing

- Robust protection circuits

- Proper EMI/EMC considerations

Sections

The PCB will include the following sections:

-

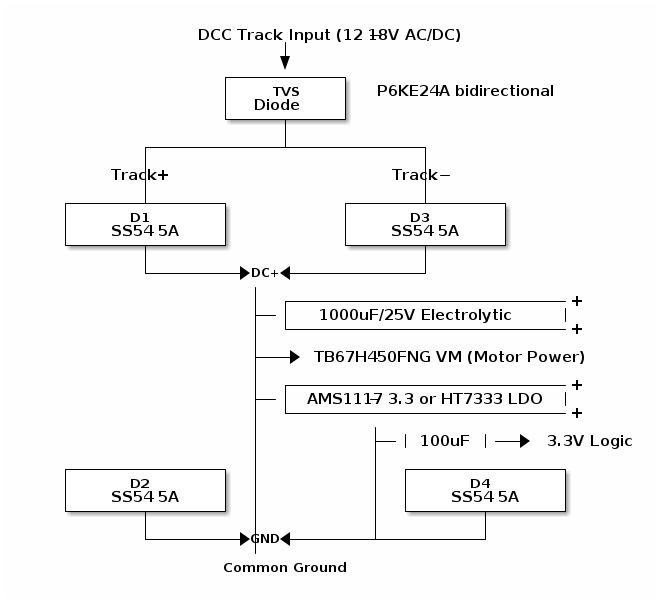

Power Supply

- Track power input with TVS protection

- Schottky diode bridge rectifier (4x SS54: 5A, 40V)

- Bulk filtering capacitors (470µF-1000µF electrolytic)

- 3.3V LDO regulator for ESP32-H2 logic

- Separate motor power feed to TB67H450FNG VM pin

- Ceramic bypass capacitors (0.1µF near ICs)

-

DCC Input Stage

- Optocoupler isolation

- Signal conditioning

- Protection diodes

-

Motor Driver

- TB67H450FNG H-bridge

- Current sense circuit (0.1Ω shunt resistor)

- Bootstrap capacitors (if needed for gate drive)

- Flyback diodes (usually internal to TB67H450FNG)

- Bulk motor power capacitor (100µF near VM pin)

-

Microcontroller

- ESP32-H2 module or bare chip

- Programming header

- Reset and boot buttons

-

LED Output

- WS2812 connector

- Level shifter (if needed)

- Power filtering

-

RailCom

- RailCom transmitter circuit

- Cutout detection

- Track coupling circuit

-

Accessory Outputs

- 2x N-FET drivers

- Screw terminals or connectors

- Protection circuits

-

Configuration

- Configuration button

- Status LED

- Optional programming port

Component Selection

Key Components

- Bridge Rectifier: 4x SS54 Schottky diodes (5A, 40V, SMA/DO-214AC) or SS56 (5A, 60V)

- Lower forward drop (~0.5V per diode, 1V total vs 2V for standard bridge)

- Better efficiency = less heat

- Fast switching for DCC frequency

- Arrange in standard bridge configuration

- Microcontroller: ESP32-H2 (RISC-V, Zigbee/Thread)

- Motor Driver: Toshiba TB67H450FNG (dual H-bridge, 3.5A)

- Optocoupler: 6N137 (fast) or PC817 (general purpose)

- N-FETs: AO3400A (SOT-23, 4A, 44mΩ RDS(on) @ 2.5V)

- For accessory outputs (max 350mA each)

- Logic-level compatible with 3.3V GPIO

- Low cost (~$0.05-0.10)

- Voltage Regulator: AMS1117-3.3 (800mA) or HT7333 (LDO, low dropout)

- Current Sense Resistor: 0.1Ω, 1W metal film or wire-wound

- LEDs: WS2812B or compatible addressable RGB LEDs

Connectors

- Motor: 2-pin screw terminal or JST-XH

- Track Input: 2-pin screw terminal

- LED Strip: 3-pin JST connector

- Accessories: 2x 2-pin screw terminals

- Programming: 6-pin header (GND, 3V3, TX, RX, IO0, EN)

Design Considerations

Power Supply Schematic

DCC Track Input (12-18V AC/DC)

|

v

+-----+-----+

| TVS | P6KE24A bidirectional

| Diode |

+-----+-----+

|

+-------------+-------------+

| |

Track+ Track-

| |

+-------+-------+ +-------+-------+

| D1 | | D3 |

| SS54 5A | | SS54 5A |

+-------+-------+ +-------+-------+

| |

+--------->DC+<-------------+

|

| +----------------------------+

+--| 1000uF/25V Electrolytic |

| +----------------------------+

|

+---> TB67H450FNG VM (Motor Power)

|

| +----------------------------+

+--| AMS1117-3.3 or HT7333 LDO |

| +----------------------------+

| |

| +--| 100uF |---> 3.3V Logic

| |

+-------+-------+ | | +-------+-------+

| D2 | | | | D4 |

| SS54 5A | | | | SS54 5A |

+-------+-------+ | | +-------+-------+

| | | |

+--------->GND<--------+----------+

|

Common Ground

Bridge Configuration:

- Track inputs: Connect to DCC rails (polarity-independent)

- DC+ rail: 10-16V after rectification

- Forward drop: ~1V total (0.5V per diode pair)

- SS54 Schottky: 5A continuous, 40V rating

- Handles motor (1-3A) + logic (~200mA) simultaneously

Component Values:

- Bridge: 4x SS54 (SMA package)

- Bulk cap: 1000µF/25V electrolytic

- LDO input cap: 10µF ceramic

- LDO output cap: 100µF electrolytic + 0.1µF ceramic

- TVS: P6KE24A or 1.5KE24CA

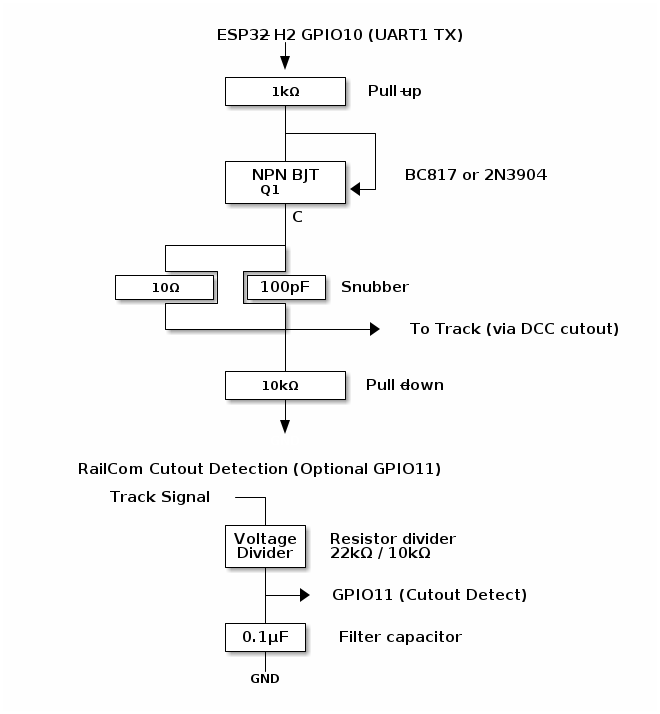

RailCom Transmitter Schematic

ESP32-H2 GPIO10 (UART1 TX)

|

v

+-----+-----+

| 1kΩ | Pull-up

+-----+-----+

|

+--------+

| |

+-----+-----+ |

| NPN BJT | | BC817 or 2N3904

| Q1 |<-+

+-----+-----+

|C

|

+-----------+

| |

+----+----+ +---+---+

| 10Ω | | 100pF | Snubber

+----+----+ +---+---+

| |

+-----------+--------> To Track (via DCC cutout)

|

|

+-----+-----+

| 10kΩ | Pull-down

+-----+-----+

|

v

GND

RailCom Cutout Detection (Optional GPIO11)

Track Signal ---+

|

+---+---+

|Voltage| Resistor divider

|Divider| 22kΩ / 10kΩ

+---+---+

|

+---> GPIO11 (Cutout Detect)

|

+---+---+

| 0.1µF | Filter capacitor

+---+---+

|

GND

RailCom Operation:

- Cutout Detection: DCC command station creates ~450µs cutout window

- Channel Timing:

- Channel 1: 26-177µs (address broadcast)

- Channel 2: 193-454µs (status data)

- Transmit: UART TX at 250kbaud during cutout

- Encoding: 4-to-8 bit encoding per RailCom spec

Components:

- Q1: BC817 NPN (SOT-23) or 2N3904

- R1: 1kΩ base resistor

- R2: 10Ω series resistor (current limit)

- R3: 10kΩ pull-down

- C1: 100pF snubber capacitor

- Cutout divider: 22kΩ + 10kΩ (scales track voltage to 3.3V)

Important Notes:

- RailCom transmits ONLY during DCC cutout window

- Requires command station with RailCom support

- Cutout detection is optional (can use timing from last DCC packet)

- Q1 must switch fast enough for 250kbaud (BC817: fT=100MHz)

Thermal Management

- Adequate copper pour for motor driver heat dissipation

- Thermal vias under motor driver IC

- Consider adding heatsink mounting holes

- Keep power traces wide (minimum 2mm for motor power)

- Bridge diodes: Place on copper pour for heat spreading

Layout Guidelines

- Keep DCC input traces short and isolated

- Star ground topology for power

- Separate analog and digital grounds near ADC

- Shield sensitive signals (DCC input, current sense)

- Keep high-speed traces short (WS2812 data <10cm)

- Proper decoupling capacitors near ICs (0.1µF within 5mm)

- Wide traces for rectifier output (2-3mm minimum)

Protection

-

TVS diode on track input (P6KE24A bidirectional)

-

Schottky diodes provide inherent fast response

-

Reverse polarity protection on track input

-

TVS diodes on all external connections

-

Overcurrent protection on motor output

-

ESD protection on user-accessible pins

Testing

- Test points for key signals (DC+, 3.3V, DCC signal, motor outputs)

- LED indicators for power (3.3V rail), DCC signal presence, status

- Easy access to programming pins

- Measure bridge rectifier forward drop (should be ~1V under load)

- Current sense test point for motor current monitoring

Future Enhancements

- Dual motor driver option

- Sound module integration (I2S DAC)

- Additional function outputs

- Servo outputs (2-4 channels)

- SUSI interface

- Optional Bluetooth antenna

Contributing

If you'd like to contribute to the hardware design:

- Use KiCad 7.0 or newer

- Follow IPC design standards

- Include clear documentation

- Provide design rationale for key decisions

- Test thoroughly before sharing

References

License

Hardware designs will be released under CERN Open Hardware License v2 - Permissive (CERN-OHL-P).

Status: Planned for future release Last Updated: 2026-01-15